News Archiv 2018-EN

The drivers played their part in this effort through five factors that contributed to safe and eco driving. Those factors are speeding; engaging the correct gear; steady driving; no engine idling and driving within the permitted hours.

Speeding means driving at a consistently high speed. Constant braking and accelerating consumes a lot of fuel and also emits CO2. This relates to engaging the correct gear. Using the wrong gear for the wrong speed could also damage the engine besides resulting in high fuel consumption. Steady driving requires the driver to not accelerate or decelerate in a sudden manner while engine idling is altogether bad for fuel and environment, although we notice this happening once too often. Lastly, driving within the permitted hours will limit the time of these heavy vehicles plying the roads and emitting CO2.

Every month there a report and ranking of "good drivers" and "bad drivers" based on an evaluated performance score is generated. The good ones will receive incentives including monetary and recognition. Those who do not comply to the five requirements above will be singled out for counselling.

Nittsu General Manager Billy Tee said with the help of incentives of "penalties", drivers' consciousness towards safety and environment has increased, as well as the working environment at Nittsu. The CDM Project also allows the management to instantly trace the drivers' driving behaviours.

The 5 new products are as follows:

$1- CAM 17K Synthetic 10W SN / CI4 – For van and light trucks

$1- CAM Dynamic (Semi Synthetic 15W 40 C14 / SL) – For heavy trucks

$1- CAM MC Synthetic (Synthetic Technology 10W 40 CI4 + / SL) – Specially formulated for the MC T Series trucks

$1- CAM Gear Oil 18000 80W 90 GL4

$1- CAM Gear Oil 19000 85W 140 GL5

Co-developed and exclusively blended by Quantum Petroleum using Australian technology, CAM lubricants use only 100% virgin base oil to ensure the highest quality base oil with no contaminations of any particles in the final product. All CAM lubricants are synthetically blended with special and unique additives packages (taken from a global renowned overseas supplier established since 1928) formulated for each specific range of CAM vehicle range.

Special exclusively manufactured additives ensure there are no sludge and rust as well as anti-wear, anti-friction and anti-oxidant. The additives also allow better low and high temperature viscosity performance at extreme service temperatures, better chemical and shear stability, decrease evaporation loss and resistance to oxidation, thermal breakdown and sludge build up problems.

The new series of lubricants introduced by CAM truly can elevate the usage and maintenance of CAM vehicles. It certainly makes fleet management fuss-free and minimises chances of vehicle breakdown.

A collaboration between Social Community Technology (Socoe) and Sarawak Lorries Transport Association will enable the providence of an online presence for truck and logistic companies in the state. The collaboration strives to elevate transportation services to better connect and improve the industry. The association which currently has more than 400 members will be able to stay connected via a platform which displays all their business information as well as allow fellow members to interact with one another online.

A collaboration between Social Community Technology (Socoe) and Sarawak Lorries Transport Association will enable the providence of an online presence for truck and logistic companies in the state. The collaboration strives to elevate transportation services to better connect and improve the industry. The association which currently has more than 400 members will be able to stay connected via a platform which displays all their business information as well as allow fellow members to interact with one another online.

Minister of Infrastructure Development and Transportation, Dr James JemutMasing said the venture makes things easier for his ministry especially in monitoring industry players and quicken the process of identifying any problems or issues that needed to be resolved immediately. “When we have so many things going around in Sarawak, it is easier for us to know what the problems that the community encounter are. We have to move on. Business changes, if we do not change, we will be left behind,” he concluded.

Present at the event were Marcus Chai (Socoe Chief Operations Officer), Phur Pui Ann (Sarawak Lorries Transport Association Chairman), Dr James JemutMasing (Minister of Infrastructure Developent and Transportation), Peter Wong (RH Vision Managing Director) and Samuel Wong (Socoe founder and Chief Executive Officer).

Customers frequently sing praises about the performance of the air conditioning compressors made by Chengdu Redin Technology. Amongst the feedback given were competitive pricing, energy saving and efficiency as well as outstanding performance.

The company aims to enhance the quality of the brand and to constantly adhere to producing only high quality products to ensure customers only get the best that the company can offer. The company complies strictly with ISO/TS 16949 standards in its effort to provide customers with cost-effective and yet highly-reliable products. It also aims to promote the development of China’s automotive air conditioning compressor technology in the local market as well as the global market amongst the industry giants that have long established their name.

The company hopes that with their participation at the recently held Chengdu International Trade Fair for Automotive Parts and Aftermarket Services(CAPAS) held from 24 to 26 May 2018, they can gain further recognition for their products in addition to gaining exposure amongst the local and international visitors to the expo.

Daimler Commercial Vehicles Thailand Co., Ltd (DCVT) has officially appointed Bangkok based “BKK Commercial Vehicle Limited” as an Authorized FUSO Dealer. The first showroom located on Srinakarin road will be a full fledge 3S (Sales, Service, Spare parts) dealership on 4 rai of land. BKK Commercial Vehicle also have plans to further expand to additional locations in the coming months. DCVT, the distributor of Fuso Trucks in Thailand, plans to expand their dealer network to 37 locations nationwide within 2018 to best serve the growing commercial vehicle market. BKK Commercial Vehicle is part of the BKK Group, Thailand’s leading car dealerships with multiple brand under its care including Mercedes Benz cars. “DCVT is very excited to welcome the newest member to the Fuso family, we are confident that we will increase retail figures and our touchpoints will be ready to serve all our trucks, existing and new” Mr. Sascha Ricanek stated.

Daimler Commercial Vehicles Thailand Co., Ltd (DCVT) has officially appointed Bangkok based “BKK Commercial Vehicle Limited” as an Authorized FUSO Dealer. The first showroom located on Srinakarin road will be a full fledge 3S (Sales, Service, Spare parts) dealership on 4 rai of land. BKK Commercial Vehicle also have plans to further expand to additional locations in the coming months. DCVT, the distributor of Fuso Trucks in Thailand, plans to expand their dealer network to 37 locations nationwide within 2018 to best serve the growing commercial vehicle market. BKK Commercial Vehicle is part of the BKK Group, Thailand’s leading car dealerships with multiple brand under its care including Mercedes Benz cars. “DCVT is very excited to welcome the newest member to the Fuso family, we are confident that we will increase retail figures and our touchpoints will be ready to serve all our trucks, existing and new” Mr. Sascha Ricanek stated.

Bogdan Simonia, Director and Head of Research and Development for Continental Automotive Components Malaysia Sdn Bhd told reporters that Continental aims to build highly competent engineers in the automotive domain.

“The future is in software development and with the C.Drive Programme. The programme will also create a sustainable hiring avenue that always offers a pool of Engineers in the making,” he added.

The C.Drive Programme is designed to engage fresh engineers and equip them with all necessary skills for Automotive Software Development. The programme includes interactive class room sessions, a self-study period as well as time bound team assignments. During these activities, they will have the opportunity to work with experts in the actual working environment and experience real projects, which will further develop their expertise.

The program offers both technical and soft skills, thus emphasising not only on engineering topics but also on personal interaction skills that are crucial for having successful careers. The six-month programme will be available on a yearly basis with the first batch beginning sometime in July this year. Application period closes by the end of June.

Simonia said a background in engineering is not compulsory but definitely a great advantage for applicants. "What's important is their willingness to learn," he said, adding that Continental has yet to partner up with any universities.

Under this programme, trainees are entitled to a monthly allowance of RM2 800, contribution to EPF, SOCSO and EIS, and various insurance packages. They are also entitled to RM100 of dental or optical treatments as well as annual and compassionate leaves.

Awards will be given to outstanding trainees namely the Best Project Award, Excellence Award and the C.Drive champions will secure a permanent position with Continental Automotive Components Malaysia. This programme will be held in Penang.

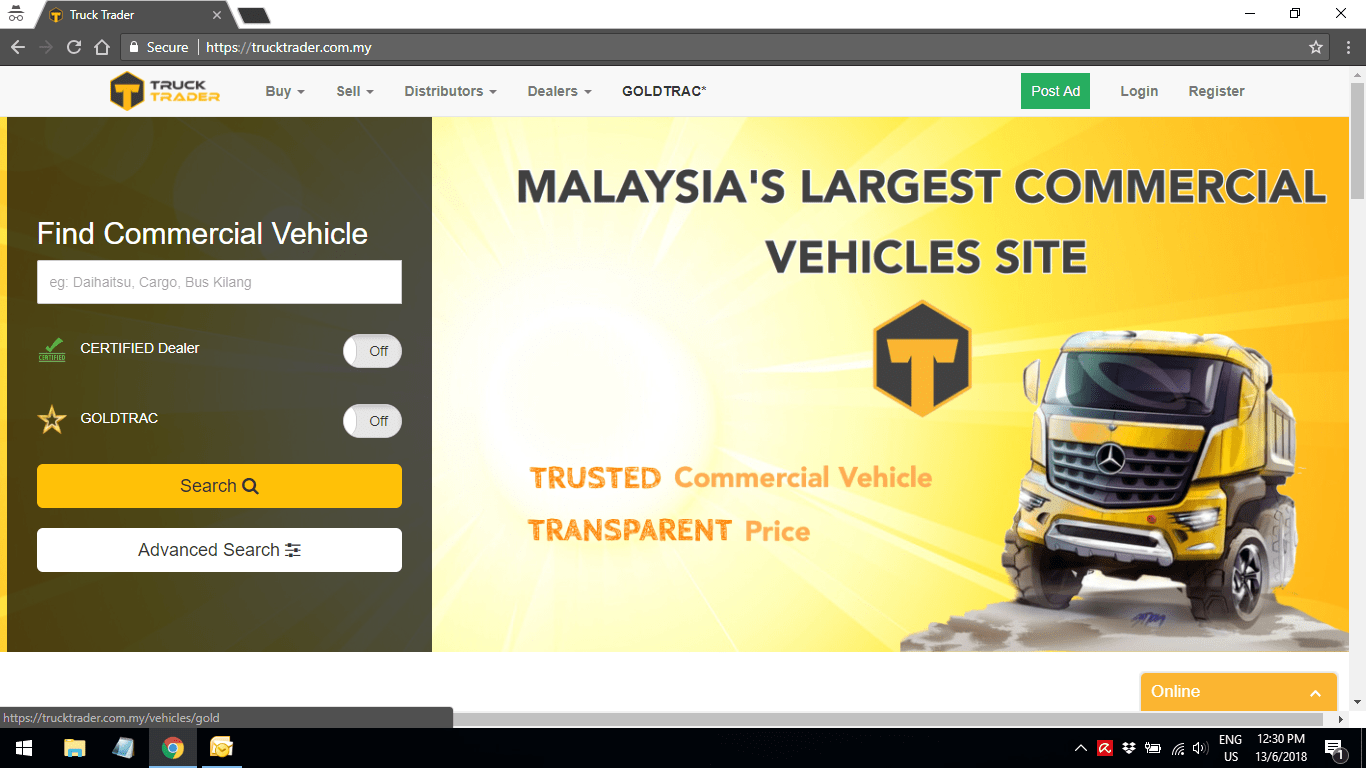

TruckTrader is an online platform for the trading of commercial vehicles here in Malaysia. Launched in 2017, the company is formed with a mission to match all commercial vehicle dealers and consumers in one place.

TruckTrader is an online platform for the trading of commercial vehicles here in Malaysia. Launched in 2017, the company is formed with a mission to match all commercial vehicle dealers and consumers in one place.

The website currently has about 500 commercial vehicles for sale on their platform, split into brand new, used or rebuilt. The types of commercial vehicles that you can find on their listings include vans, cargo trucks, food trucks, tippers and more. To use their platform, users will need to register for an account and select one of four types; distributor, dealer, sales agent and a regular member. Buyers of commercial vehicles can also request for quotations and contact the seller directly through the TruckTrader platform.

As most trading platforms face the common problems of quality of listings and price, the TruckTrader team has a system to monitor the vehicle prices. The system will detect the best value based on a certain range of mileage and the year of production of vehicle. TruckTrader also has a GOLDTRAC system that helps maintain the quality if listings by showing vehicles that follow on-the-road prices with no hidden costs.

Transparency is one the key elements the platform prides itself in when compared to other online platforms of similar nature in the market.

UD Trucks和陈唱工业用具有限公司(TCIE)首开先河,隆重推出第一部本地组装的UD Croner中型卡车,双方之间的合作再次跨越新里程碑。马来西亚UD Croner中型卡车的组装线设于陈唱摩多装配有限公司(TCMA)的泗岩末厂房,这也是UD Trucks首个设在日本以外的Croner中型卡车组装基地。

UD Trucks和陈唱工业用具有限公司(TCIE)首开先河,隆重推出第一部本地组装的UD Croner中型卡车,双方之间的合作再次跨越新里程碑。马来西亚UD Croner中型卡车的组装线设于陈唱摩多装配有限公司(TCMA)的泗岩末厂房,这也是UD Trucks首个设在日本以外的Croner中型卡车组装基地。 More than 200 participants from the cement, quarry and construction sectors at the Shell Malaysia Technovation 2018 had the opportunity to gain insights from industry experts on some of the opportunities and challenges present as infrastructure developments continue to drive the country forward.

More than 200 participants from the cement, quarry and construction sectors at the Shell Malaysia Technovation 2018 had the opportunity to gain insights from industry experts on some of the opportunities and challenges present as infrastructure developments continue to drive the country forward.

Among the country’s major infrastructure projects are the Mass Rapid Transit Line 2 (MRT2), the Pan-Borneo Highway or PBH and the much talked about high-speed rail (HSR) linking Malaysia and Singapore.

Others include the Forest City mixed development project and Robotic Future City in Johor, Melaka Gateway, Kuala Linggi International Port, Kuantan Port expansion, waterfront land reclamation in Penang and a green technology park in Pahang.

While all these multi-billion ringgit projects looked set to present tremendous opportunities to local companies, there were also various challenges involved.

Professor Dr Cheng Ming Yu of the Belt and Road Strategic Research Centre, University Tunku Abdul Rahman, took the opportunity to share insights on how Malaysian companies could benefit from the much talked-about Belt and Road Initiative (BRI).

“The primary objective of this China-led initiative is to establish connectivity through infrastructure, cultural and technological exchange to promote mobility and achieve sustained economic progress. For local companies to participate actively and benefit from BRI, they need to know how to manage the inflow of capital, people and technology and be ready to face challenges brought by rapid changes in the global environment. This calls for continuous investments and upgrading in education, training, human capital development, and technologies,” she said.

Tunnelling expert Ir Syed Rajah Hussain Shaib from The Institution of Engineers Malaysia (IEM) pointed out that many infrastructure projects now required the deployment of new technologies such as tunnelling to reduce the impact on the natural environment.

He called for institutions of higher education to update their syllabuses accordingly to meet the human capital needs for the use of such advanced technologies.

His colleague in IEM, Ir Derick Chia, then spoke on the complexity of project management and the importance of preventive maintenance on machinery to ensure timely delivery at each stage of a project.

“Machine is definitely one of the five key elements of project management as any breakdown will interrupt work activities on site. Delays could be extremely costly as the contractor could end up paying the full penalty, which is 15% of the total contract amount.

Hence, we strongly urged the project managers or site managers to pay serious attention to the ‘machine integrity’ issue. The ‘machine’ element might not comprise a huge portion of the entire project cost, but it definitely will impact the project schedule, especially those that involved a large portion of site installation works,” he said.

At the conference, two Shell experts on lubricant technology also shared their views and knowledge on the crucial roles of lubricants in ensuring machine integrity and availability and their impact on total cost of ownership with the participants.

Lubricants technical specialist Dr Felix Guerzoni from Shell Shanghai Technology Centre highlighted the extensive range of lubricants developed by Shell to meet the needs of increasingly sophisticated machinery used in infrastructure development projects, including the Shell Naturelle range of biodegradable lubricants suitable for sensitive environments.

Meanwhile, Shell Global Technical and OEM Manager Karen Lee touched on how private companies, including lubricants suppliers such as Shell, could play a role in supporting infrastructure developments in Malaysia.

As the largest lubricant supplier in the world for the past 11 years[1], Shell has the right products and technical expertise to help construction companies improve their machine availability by using the correct lubricants to lower maintenance costs, reduce equipment downtime and achieve higher productivity.

Shell Malaysia Technovation is an annual technology conference organised by Shell Malaysia Industrial Lubricants units for its customers across the industries.

As an official sponsor of Team Hahn Racing, Kögel will of course be represented at the 33rd International ADAC Truck Grand Prix from 29 June to 1 July 2018 at the Nürburgring. At stand R27, Kögel will be exhibiting the Lightplus, one of the first trailers of the NOVUM generation. In addition to an autograph session with four-time European champion Jochen Hahn, a fundraising campaign for professional drivers and Kögel fan merchandise, there will be many other surprises and campaigns at the Kögel stand.

As an official sponsor of Team Hahn Racing, Kögel will of course be represented at the 33rd International ADAC Truck Grand Prix from 29 June to 1 July 2018 at the Nürburgring. At stand R27, Kögel will be exhibiting the Lightplus, one of the first trailers of the NOVUM generation. In addition to an autograph session with four-time European champion Jochen Hahn, a fundraising campaign for professional drivers and Kögel fan merchandise, there will be many other surprises and campaigns at the Kögel stand.The payload and weight-optimised Kögel Lightplus offers a low tare weight in its basic version, as well as the advantages of the NOVUM generation. These include the air and lighting console on the front wall, which transfers forces along the side member to the frame, the new external frame profile, which significantly increases the accessibility of the VarioFix lashing points, and the variable slat pockets.

Truck racing champion Jochen Hahn will be appearing at the Kögel stand to meet and greet fans on 30 June at 1 pm. Jochen will of course be happy to answer fans' questions and sign autographs.

Volvo Trucks’ annual Fuelwatch Challenge is back this year, to continue with Volvo’s aim to promote maximum fuel efficiency and proper driving skills. The competition is open to drivers across Malaysia with two separate categories, the closed category and the open category.

Volvo Trucks’ annual Fuelwatch Challenge is back this year, to continue with Volvo’s aim to promote maximum fuel efficiency and proper driving skills. The competition is open to drivers across Malaysia with two separate categories, the closed category and the open category.• Mohd Sufian bin Sahari – Multimodal Freight Sdn Bhd

• Mohd Zamry bin Mohd Nasir – Syarikat Jasa Selamat

http://www.asiantrucker.com/newsevents/calendar/month.calendar/2018/06/05/-

Volvo Trucks Malaysia recently hosted a vehicle handover ceremony for its long-time customer – Taipanco Sdn Bhd. The official handover of 10 units of Volvo FM440 6x2 prime movers was held at Taipanco’s office at Bandar Suleiman, Port Klang and was attended by the senior management team members of both companies. The handover ceremony started with a welcoming speech from Volvo Trucks Managing Director, Mats Nilsson, followed by a presentation of a truck scale model and mock key to commemorate the occasion.

Volvo Trucks Malaysia recently hosted a vehicle handover ceremony for its long-time customer – Taipanco Sdn Bhd. The official handover of 10 units of Volvo FM440 6x2 prime movers was held at Taipanco’s office at Bandar Suleiman, Port Klang and was attended by the senior management team members of both companies. The handover ceremony started with a welcoming speech from Volvo Trucks Managing Director, Mats Nilsson, followed by a presentation of a truck scale model and mock key to commemorate the occasion.

Taipanco Sdn Bhd, together with its wholly-owned subsidiary, Shallas Sdn Bhd specialize in container haulage, warehousing and freight forwarding services. The company mainly services the two major ports in Malaysia, namely The Westport and Northport, both of which are located in Port Klang. The company has been a great supporter of Volvo Malaysia, with more than 130 trucks purchased since 2005. The additional units of Volvo FM440 delivered are part of Taipanco’s continuous fleet expansion plan.

Dato’ Nazari Haji Akbar, Executive Director of Taipanco Sdn Bhd said, “We believe that having a dependable truck fleet is one of the key factors that contribute to our business growth. In the past decade, Volvo Trucks has been partnering with us along our growth journey by continuing to provide us with durable products and reliable after-market services.”

The guests who attended the ceremony were also treated to a unique experience in the Volvo exhibition trailer in which the guests were able to view videos of Volvo Trucks’ products and innovative technology.

“We are very pleased to host this handover ceremony for our very valued customer and business partner, Taipanco Sdn Bhd, whom we have established a good relationship with for many years,” said Mats Nilsson, Managing Director of Volvo Malaysia.

“With our flagship workshop located right next to Taipanco’s operation base here in Port Klang, we are fortunate to be so close to each other, enabling Volvo Malaysia to provide the best support that we can to ensure vehicle uptime.”

Part of Volvo Trucks’ mission is to provide quality both in terms of products and service. With that in mind, Volvo hopes to continue developing a close customer relationship with Taipanco as well as all their customers, by listening and understanding the changing needs of the customers and responding to them quickly.