IAA 2016: Continous Innovations and Intense Drive from Lamilux

By now one should be used to Lamilux being a powerhouse of innovations. Again, at the IAA 2016, the company comes through with the presentation of new solutions, coupled with staff driven to go the extra mile.

By now one should be used to Lamilux being a powerhouse of innovations. Again, at the IAA 2016, the company comes through with the presentation of new solutions, coupled with staff driven to go the extra mile.

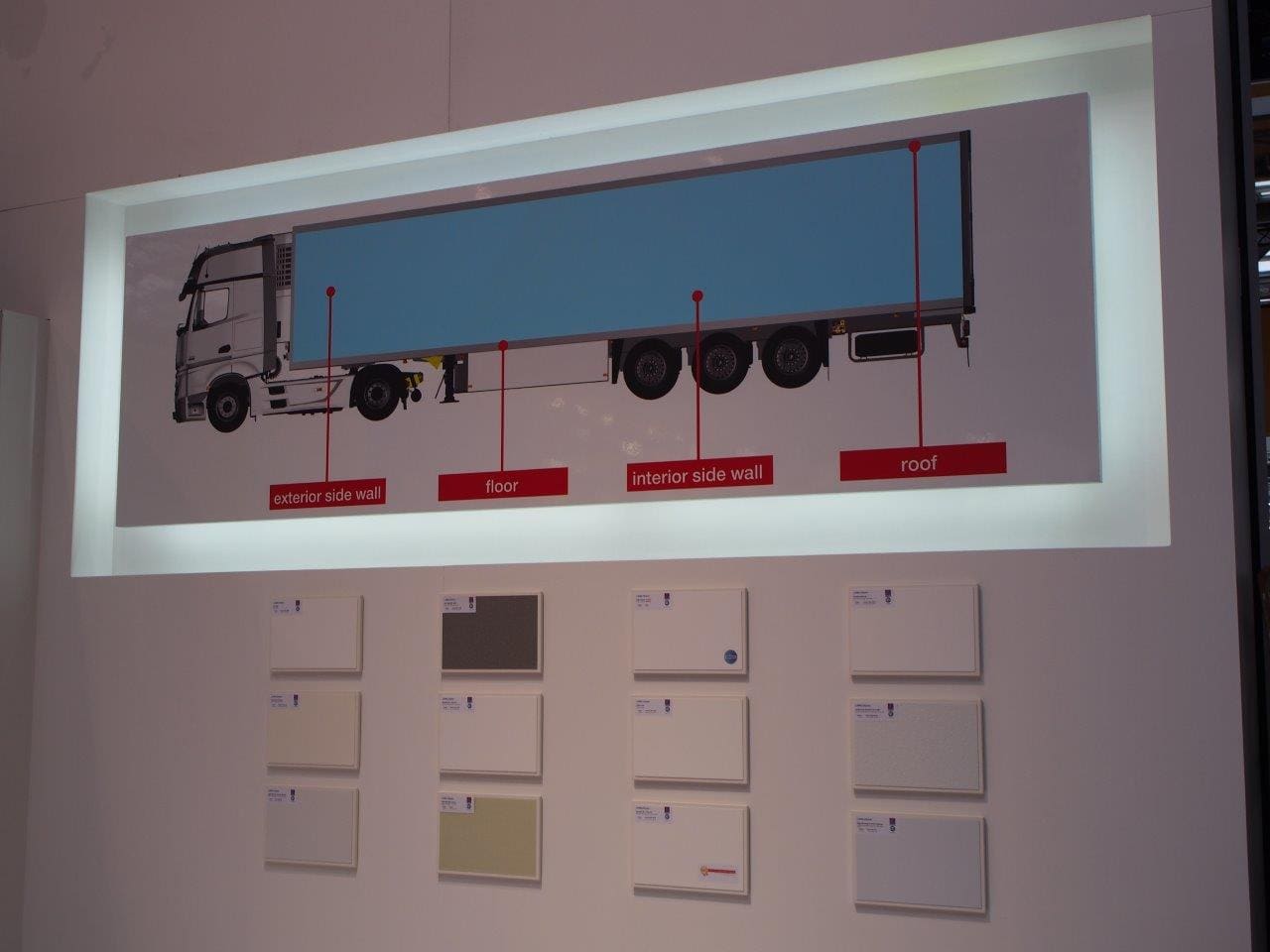

Taking us through the innovations is Mr. Christoph Meiler, Sales Manager for innovative fibreglass solutions. The first product Lamilux is featuring at the IAA is their anti-bacterial solution, which works with all their Gelcoats. Through this, 99.9 % of bacteria are killed upon contact with the surface. Lamilux’s AntiBac is tested and certified and can last decades. What is interesting is that the product was initially developed for applications in the medical industry. “AntiBac was conceptualised for mobile hospitals. I point out that the bacteria are permanentely killed upon contact,” said Meiler. For the commercial vehicle industry, Anti-Bac is suitable for reefer trucks and any transport solution that is dealing with food. “We have already gathered some good feedback from companies active in food transportation,” he added.

Next he shows us the Lamilux High Strength X-treme Gelcoat. Through special ingredients, this laminate offers an extreme flexural strength, tensile strength and modules of elasticity. Meiler said that “You can apply this directly on a frame, without the need for a plywood frame. That obviously saves weight.” Adding to that, Lamilux is showing their solution for anti-slip. “Here we can immediately make use of the laminate, unlike in the traditional production method, which required the material to dry for two to three days. The time savings in the production are tremendous when using our product.” One key trend Lamilux has identified is the departure from steel and other metals when building commercial vehicle bodies. The industry is looking for lighter weights, which offer higher payloads, while making better use of resources.

Here at the IAA we are also meeting with Mr Louis Mary, Southeast Asia Sales Manager. He joined Lamilux in the beginning of the year to handle the South East Asian market. Previously he was already in the composite industry, however his scope of work was not specifically on the materials side.

Focus South East Asia Market

“For me, it was an interesting market to start with in the sense of diversity and dynamics. There are quite a few countries in Asia, obviously with different languages, different rules and different habits, especially when it comes to commercial vehicles,” is a short summary he has about his initial experience.

“From our perspective, we see a lot of potential for our business growth in the market. We slowly shift the mentality to accept innovative changes and as we expected, some countries are going slower than others, but nevertheless, we will get there eventually.”

“As for my short experience, I could say, Thailand is very receptive, as is Vietnam and Singapore towards our products. He continued to say that “Our aim is to add value to the market with our high quality products and backing them with support because we are based in South East Asia. Apart from that, we strive to deliver a better support to our customers than our competitiors.”

“My job here at the IAA is help expanding our network plus meeting existing and new customers. I do my best in presenting our new products to convince our customers to give us a chance to prove their value.”