Quietly and eco-friendly through the city

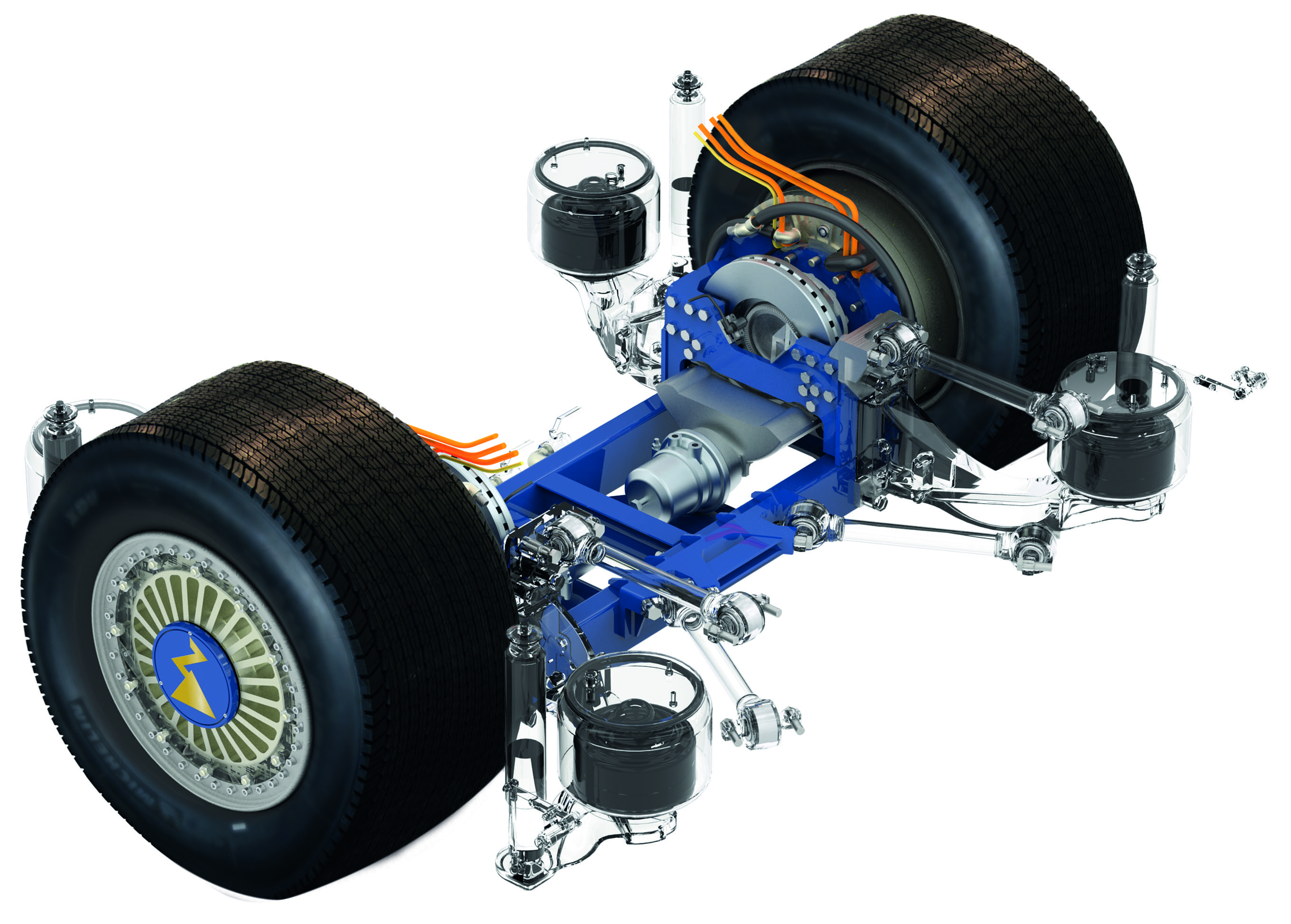

Ziehl-Abegg presents the ZAwheel: Electric in-wheel hub drive without transmission Ziehl-Abegg is applying its more than 100 years of experience in the construction of electric motors. In the past such drives could be found in elevator motors, in fans and in special vehicles. "Our goal has always been to reduce the energy requirement, to minimise the operating noises and to construct high class motors that perform their duties lastingly and reliably" Arnold explains.

Ziehl-Abegg presents the ZAwheel: Electric in-wheel hub drive without transmission Ziehl-Abegg is applying its more than 100 years of experience in the construction of electric motors. In the past such drives could be found in elevator motors, in fans and in special vehicles. "Our goal has always been to reduce the energy requirement, to minimise the operating noises and to construct high class motors that perform their duties lastingly and reliably" Arnold explains.

The gearless wheel-hub drive was also exhaustively scrutinized and tested by various partners. For many years it has been in scheduled service use in various countries in field trials before deciding in favour of the market launch at this time. Consequently, the statements made on consumption and efficiency are based on verified measurements. "We have cut the energy consumption in half as compared with buses using combustion engines" the motor expert Arnold emphasizes. The fact is that combustion engines achieve an efficiency of just 22 to 30 percent. A conventional electric motor with a frequency inverter reaches 85 percent. "And we increase the efficiency to even 90 percent" says Arnold.

That is possible because in the ZAwheel shift, differential, or simple reducing gears are no longer needed. And that is because the motor sits in the middle of the wheel. Of course it goes without saying that the energy does not get lost during braking; rather it is fed back into the battery. "It is exactly in commercial vehicles such as city buses, which have to start and brake often, that the efficiency is especially reaped through the energy recovery" Arnold underscores. On top of that road users, passengers and residents are spared 90 percent of the traffic noise. "A significant plus in life quality."