News 2020 EN BUS

Yutong Sells First Electric Bus in Scotland

Pelican Bus & Coach, the UK and Ireland importer and distributor for Yutong Buses and Coaches, has made its first sell with a Yutong E12 bus to McGill’s Buses, the largest privately-owned bus and coach operator in Scotland. The order was placed following a successful trial with a Yutong E12 last year.

Pelican Bus & Coach, the UK and Ireland importer and distributor for Yutong Buses and Coaches, has made its first sell with a Yutong E12 bus to McGill’s Buses, the largest privately-owned bus and coach operator in Scotland. The order was placed following a successful trial with a Yutong E12 last year.

Delivery of the Yutong E12 bus will take place prior to the United Nations Climate Change Conference COP26 in Glasgow in November, as part of what McGill’s Managing Director Ralph Roberts says “is the start of McGill’s zero-emission journey.” McGill is the main Scottish private bus operator with nearly 1,000 employees, four depots, over 400 buses and a network of around 110 routes.

The E12’s range between charges is according to Roberts one of the reasons that McGill’s has chosen for the Yutong product. The 12-meter Yutong E12 has a single Yutong YTM280-CV9-H electrical PMSM drive motor with maximum power of 350 kW and 2,400 Nm torque. Both axles are from ZF with a ZF AV132 as drive axle. The battery is a LFP (Lithium Iron Phosphate) with a total of 324 kWh capacity. Regenerative braking system extends the range.

MAN - More Tips for When Your Vehicle Stands for a While

Following yesterdays posting, Man Truck & Bus Malaysia shares more useful tips that can be helpful to maintain

operational readiness beyond the current restrictions, whenever a vehicle may be parked for some time. While this is highly applicable during this time of Movement Control, these tips are also useful in case you have to park your vehicles for a time in other circumstances.

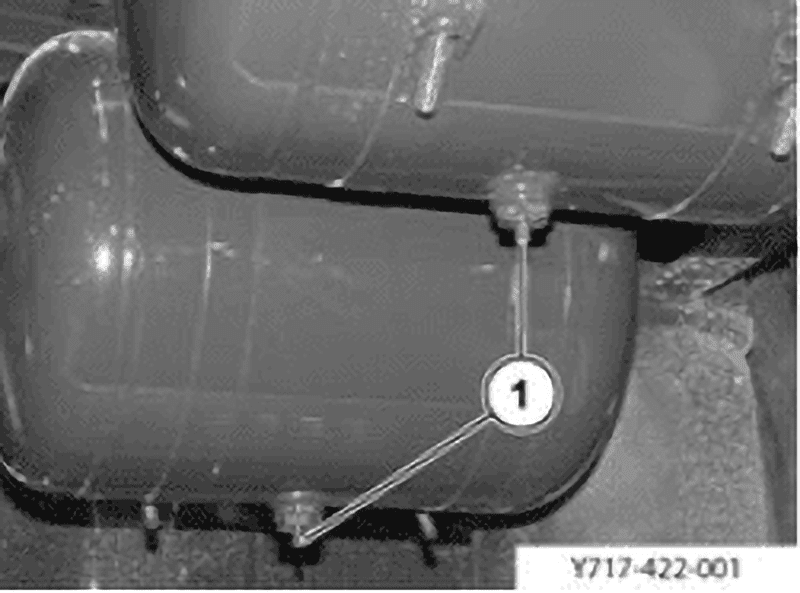

Tip 3 - Drain compressed air reservoir

Dry the area on the water drain valve 1 and pressed the drain valve 1 from the side using a suitable tool.

*only air should emerge, if condensation emerges:

- Drain entire compressed air reservoir.

- Drain the compressed air reservoir again after a week.

If condensation persists please contact local MAN service center.

Tip 4 – Warming up

- The coolant temperature increases very slowly at idling speed under little load. Therefore, do not run the engine to warm it up at a standstill.

- Instead, warm up engine under medium load. This is the most efficiency way for the engine, gearbox, and drive axles to reach their operating temperature .

Tip 5 - Engine operating oil pressure

Make sure the oil pressure at the range (1.2 to 1.5 bar) when idling.

Same process as tips 2 (see post from yesterday) to check engine oil pressure, with engine running.

Thought Leaders: Gyration 2.0: Kinetic Ignition

In an exclusive interview with Asian Trucker, Michael Hutt, Group Marketing Manager Kit Loong Commercial Tyre Group tells us more about the ins and outs of the recently held Gyration 2.0: Kinetic Ignition event.

In an exclusive interview with Asian Trucker, Michael Hutt, Group Marketing Manager Kit Loong Commercial Tyre Group tells us more about the ins and outs of the recently held Gyration 2.0: Kinetic Ignition event.

In terms of timing, some might have raised an eyebrow as it was held right around Chinese New Year. However, according to Hutt, there was a good reason to start the year with a bang. “We have spent last year to re-align our business, the brand and our product and service offerings. And this is how we are planning to communicate this,” explained Hutt. There are to be now three distinct segments of the business and each one will have its own event series.

According to him, one segment is related to Giti products. It is probably the biggest growing tranche for Kit Loong Commercial Tyre Group and this is the reason why the Gyration event series was the first to be initiated with the first instalment taking place last year. In that connection, Kit Loong Commercial Tyre Group is aiming to shift their focus from being purely a tyre-seller towards their service-based business that offers support beyond just product.

Although most people are very aware of how to look after tyres, Kit Loong Commercial Tyre Group realises that certain things will have to be brought back to peoples mind. For instance, heat build-up is highly destructive for tyres and can have a highly negative impact on the re-treadability of the tyre. As an exclusive event for existing customers, the Gyration 2.0: Kinetic Ignition event was to educate users about both heat and the 3R concept of Reduce, Reuse and Recycle. “It is important to note that Giti has already made public statements that they want to sell fewer tyres as they want users to be able to run tyres for longer.” In Hutt’s words, this is where Kit Loong Commercial Tyre Group is breaking new ground as they are actively helping to achieve this goal.

A paradigm shift is happening within Kit Loong Commercial Tyre Group as they see tyres as an investment that needs to have planned maintenance in place to ensure that the return on the investment is as high as possible. To demonstrate what is possible, Kit Loong Commercial Tyre Group is giving away their newly developed software for free for the first year. Not stopping there, they are also including a retread voucher for each new tyre sold. The discount on the retread is based on the grading of the tyre when it comes back for retreading. “Essentially, it pays to look after your tyres as you will save on the retreading. And if you don’t look after your tyre, no matter what brand, it will not perform as well as it could, as many are now designed for two or three retreads.”

Volvo Buses in Indonesia – The Tale of Two Cities

One year after Volvo Buses launched their products to the Indonesian bus market, they are taking one step further bringing their premium coach, the Volvo B11R, to Jakarta and inviting people to experience a first-hand Ride and Drive.

One year after Volvo Buses launched their products to the Indonesian bus market, they are taking one step further bringing their premium coach, the Volvo B11R, to Jakarta and inviting people to experience a first-hand Ride and Drive.“Customer experience is essential to business success. At Volvo Buses, our promise is to be the best business partner to our customers. The aim of this Ride and Drive is to take our vehicle to our customers and give them an opportunity to ride, drive and learn more about the benefits a Volvo vehicle can offer their business. Our relationship with our customers does not stop when we handover the keys to their new vehicles. We have the product that meets every requirement and also the service to back it up. Volvo Buses are really excited to spend the time with our customers face to face,” said Mr. Mats Nilsson, Director of Volvo Buses APAC Central.

The Ride and Drive kicked off at PT Wahana Inti Selaras, Indomobil Tower in Jakarta. The experience then saw participants take a tour around South Sentul City for approximately 4 hours starting from Sentul Lake Resort and Hotel. Sentul City is known for its picturesque scenery, low traffic, and a mix of high and low ground. Participants enjoyed mixed road conditions which allowed them to gain the full experience of driving a Volvo coach.

“This was an opportunity not to be missed,” said by Bambang Priyono, Director of PT Wahana Inti Selaras, sole distributor of Volvo Buses in Indonesia. “It was a good chance for our customers to get in the coach and experience how the Volvo product performs under realistic conditions. The public were also able to enjoy the luxury of a Volvo coach with a free ride - which we believe helps build up the Volvo brand in Indonesia.”

The onsite support team from PT Indotruck Utama (ITU), a subsidiary of Indomible Group, sole distributor of Volvo Buses in Indonesia, offered their extensive knowledge of the industry and explained the enhanced power, performance, efficiency and reliability of the Volvo B11R and a number of extensive services provided by ITU. Professional driver trainers were also present to accompany customers throughout the Ride and Drive and provide an overall safe and pleasant journey.

With the support of Volvo’s customer, PT. Rosalia Indah Transport, one Volvo B11R ultra-high deck was operated throughout the event. The striking Volvo B11R is 13.3 meters long, bodied by PT. Adi Putro Wirasejati. It features 6x2 axles with full air suspension, a 430hp engine and a 6-speed full auto gearbox with a built in retarder.The vehicle is designed with high floors for wider and higher luggage capacity and can carry up to 5 motorbikes at the same time. The chassis also comes with the Volvo industry leading 12-speed I-Shift AMT transmission - designed to meet various needs of long distance and inter-city transportation.

With the support of Volvo’s customer, PT. Rosalia Indah Transport, one Volvo B11R ultra-high deck was operated throughout the event. The striking Volvo B11R is 13.3 meters long, bodied by PT. Adi Putro Wirasejati. It features 6x2 axles with full air suspension, a 430hp engine and a 6-speed full auto gearbox with a built in retarder.The vehicle is designed with high floors for wider and higher luggage capacity and can carry up to 5 motorbikes at the same time. The chassis also comes with the Volvo industry leading 12-speed I-Shift AMT transmission - designed to meet various needs of long distance and inter-city transportation.Rosalia Indah Transport is one of the biggest bus operators from Solo City, Central Java, and mainly operate round trips from Jakarta to Jember, East Java. The company currently has 2 Volvo B11R ultra high deck coaches and 5 units more on the way - which are expected to hit the road by mid-2020.

With mobility in their blood, Volvo Buses has also left a footprint in Surakarta, in the island of Java, Indonesia. Volvo Buses brings their city bus, the Volvo B8RLE, to test drive in Surakarta City (also called Solo City), in the central of Java Island, Indonesia.

“On behalf of Volvo Buses, we are extremely excited to bring our city bus – the Volvo B8RLE – to Surakarta City, in the central of Java Island. Known as the most populated island in the world, we hope that by introducing our advanced product and modern technology to the people, we may be able to influence the future development of public transport on the Island. Volvo Buses highly appreciate the trust and support from the City Government thus far,” said Mats Nilsson, Director of Volvo Buses Region Asia Pacific Central.

Attended by the Mayor of Solo, the Head of Solo City Transport Agency, Solo’s Chief of Traffic Police and other Solo City Government officials, the test drive of the vehicle was carried out over 3 days and drove through several planned routes around the city.

Attended by the Mayor of Solo, the Head of Solo City Transport Agency, Solo’s Chief of Traffic Police and other Solo City Government officials, the test drive of the vehicle was carried out over 3 days and drove through several planned routes around the city. The body, manufactured by Indonesian bodybuilder. CV. Laksana, are one of the leading bus body body builders in Asia. Built to meet the needs of urban traffic environments, the bus is12 meters long, is wheelchair accessible and has capacity of up to 80 passengers.

The body, manufactured by Indonesian bodybuilder. CV. Laksana, are one of the leading bus body body builders in Asia. Built to meet the needs of urban traffic environments, the bus is12 meters long, is wheelchair accessible and has capacity of up to 80 passengers.MAN - Tips for When Your Vehicle Stands for a While

During the Movement Restriction Order (MRO), some fleets may be forced to stop any movement. Man Truck & Bus Malaysia shares useful tips that can be helpful to maintain operational readiness beyond the current restrictions, whenever a vehicle may be parked for some time. We share a series of these tips here and today we have the first two for you:

Tip 1 - Battery maintenance

If your vehicle is at a standstill for longer than two days, the main battery switch must be opened.

For vehicle parking longer than 1 week

- Check the batteries charge level, and if necessary, charge the batteries.

- Disconnect the electrical connection by disconnecting the negative terminal. Turning off the main battery switch is not sufficient.

- Check the charge level of the batteries regularly at a minimum interval of 8 weeks. Recharge the batteries if necessary.

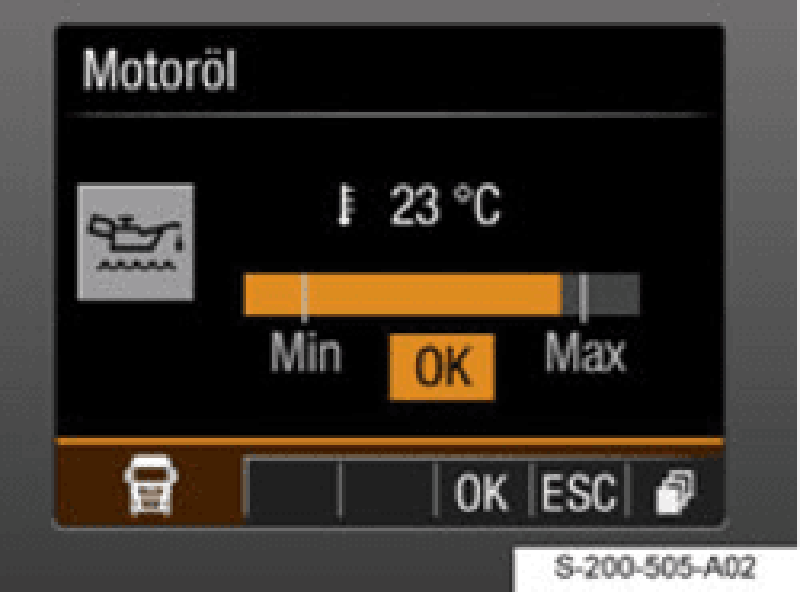

Tip 2 - Engine : checking oil level.

Below is the process to check engine oil level. Ensure correct oil level before re-starting your vehicle after a longer standstill.

i.) With engine switch off

ii.) Call up vehicle menu

iii.) Select “vehicle” menu item

iv.) Select “monitoring data” menu item

v.) Select “Engine oil” menu item

Make sure oil level is in between Min and Max range

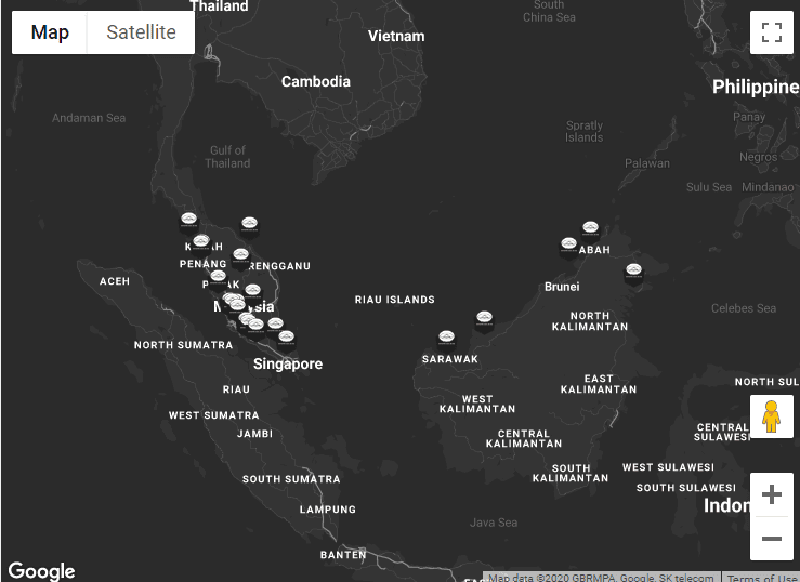

Weststar Maxus Joins Asian Trucker’s Service Network

We have now added Weststar Maxus to our service network map on the website. Locations include Johor, Kedah, Kelantan, Kuala Lumpur, Malacca, Negeri Sembilan, Pahang, Penang, Perak, Sabah, Sarawak, Selangor and Terengganu. Visit your nearest Weststar Maxus Service Centre today!

We have now added Weststar Maxus to our service network map on the website. Locations include Johor, Kedah, Kelantan, Kuala Lumpur, Malacca, Negeri Sembilan, Pahang, Penang, Perak, Sabah, Sarawak, Selangor and Terengganu. Visit your nearest Weststar Maxus Service Centre today!

Wheel Alignment of Buses – Special Considerations

Bus alignment should be done on a fully assembled bus and not on the bare bus chassis prior to the bus body being built up on it. This is because the weight of the bus body will affect the wheel alignment parameters. Also because the bus body should be used as the wheel alignment reference as the following explanation will show.

Bus alignment should be done on a fully assembled bus and not on the bare bus chassis prior to the bus body being built up on it. This is because the weight of the bus body will affect the wheel alignment parameters. Also because the bus body should be used as the wheel alignment reference as the following explanation will show.

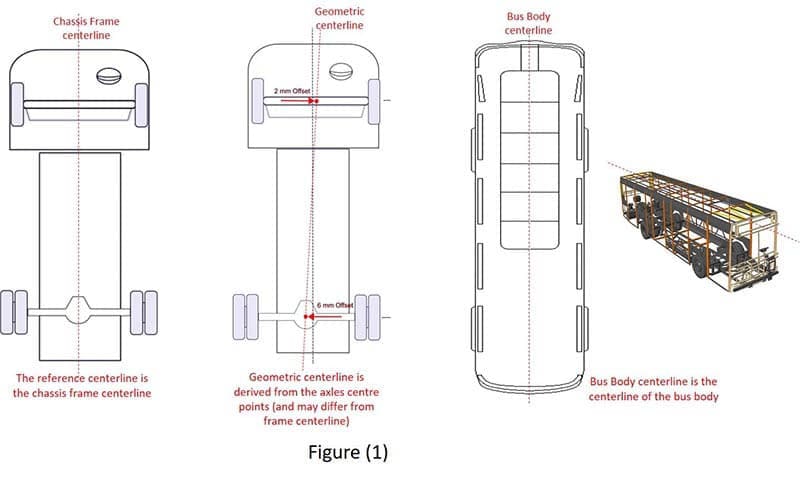

All alignment systems have their working principle but one thing they have in common is that they have a reference line in reference to which the axles and wheels are aligned. For trucks with a chassis frame, it is logical that the appropriate reference is the chassis frame centerline. However, different alignment systems use different approaches to derive this chassis frame centerline. Some systems use the geometric centerline derived from axles center-points as the reference. If the axles are installed without any offset, the geometric centerline coincides with the chassis frame centerline.

A bus is built up from a bus chassis frame on which the bus body is assembled. In some bus design, the chassis frame may need to be cut and re-joined and then the bus body built over it. Typically, when a customer orders a bus, the OEM manufacturer delivers the bus chassis to the bus body assembler to build the bus body onto it according to OEM and the customers’ requirement.

For a bus then, in addition to a chassis frame centerline and a geometric centerline, there is also a bus body centerline as shown in this image.

If you like to know how to improve the performance of your fleet, order this book to get your bus straightened out. Available from Asian Trucker at RM 100 + Postage (info@asiantrucker.com):

The First of the BTS Shuttle Bus Launched

On 17th March 2020, the Bangkok Metropolitan Administration (BMA) launched the first of the three pilot BTS shuttle bus services, with plans to introduce seven more following the success of the initial three.

On 17th March 2020, the Bangkok Metropolitan Administration (BMA) launched the first of the three pilot BTS shuttle bus services, with plans to introduce seven more following the success of the initial three.

The launch of the first route will operate under the BMA Feeder project and was officiated by Aswin Kwanmuang, who has been serving as the governor of Bangkok from 2016. The first of the three will be travelling a 26.5-kilometre route that links the New Southern Bus Terminal to the BTS Skytrain’s Bang Wa Station. The trip takes roughly between 20 and 30 minutes, with a bus leaving in 15-minute intervals during rush hour and in 30-minute intervals during off-peak hours.

The remaining two routes, a 17.5-kilometre link between the Kheha Rom Klao and the Airport Rail Link, and a 11.7-kilometre link between Bangkok City Hall 2 and BTS Sanam Pao, will begin operation on 24 March and the week after 31 March, respectively.

A smartphone application, Viabus, has also been released to the public to allow passengers to receive real-time updates on the GPS locations of nearby shuttle buses. There will be no fee incurred for the service of the three pilot routes in the first six months of operation as this will serve as more of a trial period to gauge the public consensus. This will then be taken into account for the decision on whether to proceed with the launch of the remaining seven shuttle bus services. The proposed routes for the remaining seven will include a link between Siam Square and Sanam Luang, and another link between Thong Lor and Ekkamai.

Singapore to Get World’s Largest Depot

The world’s largest and first building-type rail and bus depot is currently under construction near Changi Airport, in the south eastern part of Singapore. The T301 Project was awarded to Korean construction and engineering company, GS E&C in March 2016 at the price of USD 1.4 billion. It is the largest project ever placed by Singapore’s Land Transport Authority (LTA).

The world’s largest and first building-type rail and bus depot is currently under construction near Changi Airport, in the south eastern part of Singapore. The T301 Project was awarded to Korean construction and engineering company, GS E&C in March 2016 at the price of USD 1.4 billion. It is the largest project ever placed by Singapore’s Land Transport Authority (LTA).

The T301 Project is attracting much attention because it is the world's largest rail and bus depot and the first building-type depot. The amounts of reinforcing rods and concrete used to build the large depot reached 300,000 tons and 1.8 million cubic meters, respectively. "The volume of the reinforcing rods is 42 times more than that used for the construction of the Eiffel Tower, and the amount of concrete is five times larger than that used for the construction of Burj Khalifa, the world's tallest edifice," shared a spokesperson from GS E&C.

The T301 Project consists of a two-story subway train depot with one basement floor and a four-story bus depot on a site of 320,000 square meters. The construction work will run for a total of 95 months. The Korean builder is aiming to complete the depot in February 2024.